Barton Malow provided design-build services for the construction of the 251,000 SF General Motors DMAX engine facility. This plant manufactures the diesel engine components for GM’s Chevy Silverado and GMC Sierra heavy-duty pickup trucks and brought approximately 100 jobs to boost the community’s economic recovery following destructive tornadoes that swept through the area.

Accelerated Schedule

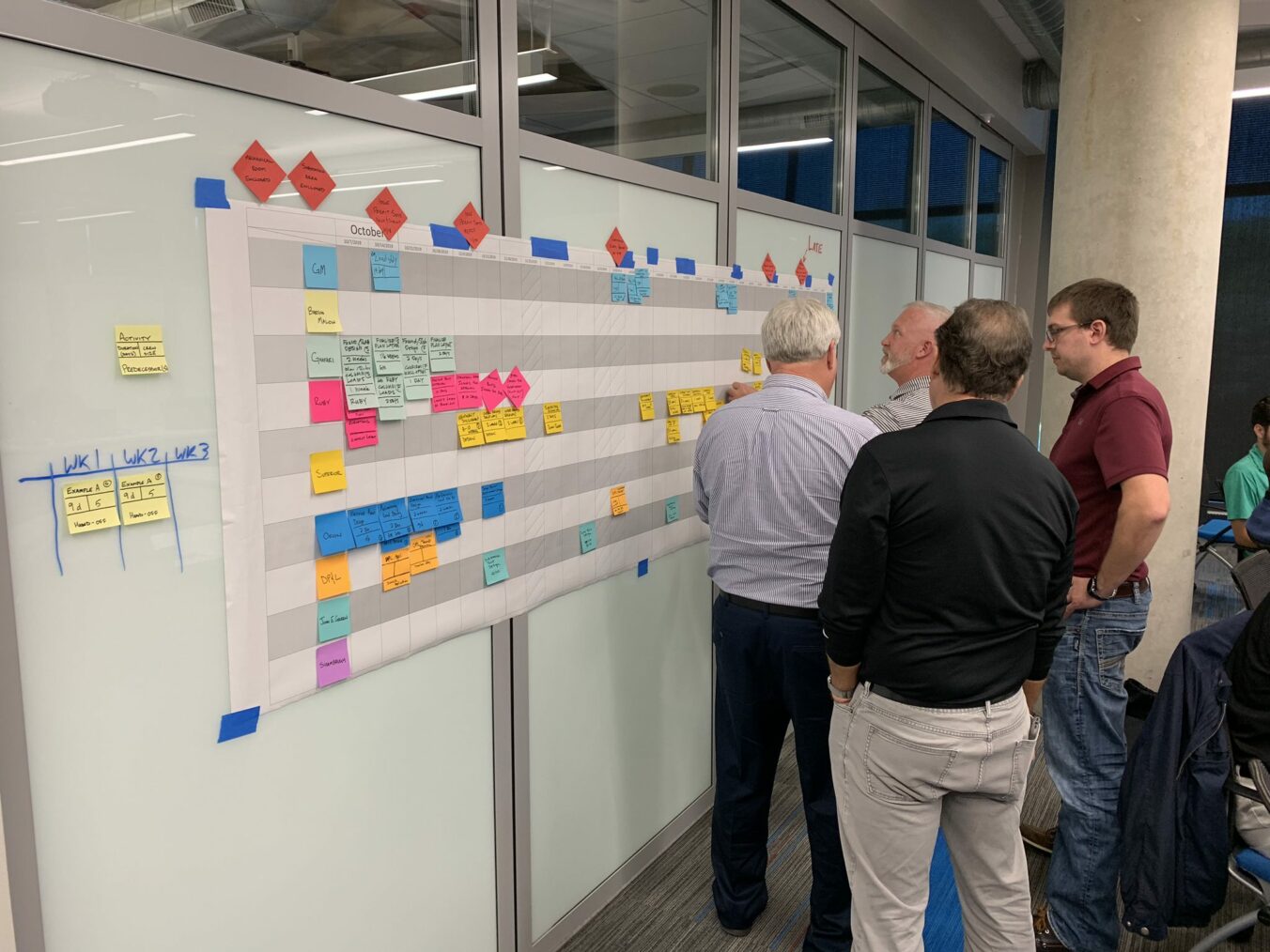

With a tight speed-to-market timeline, our DMAX engine facility construction team engaged in collaborative planning, using tools like the Last Planner® System, to align the team and develop key milestones and production plans. This accelerated the goal to have foundation work stay two phases ahead of steel placement. Overall, we saved 12 weeks in the front-end planning, design, modeling, and detailing for steel using LeanSteel practices as well as created a 20% gain in efficiency for electrical, which translated into savings for GM.

We self-performed civil, concrete, structural steel, and all equipment installation, totaling more than 75,000 safe work hours, which earned us the National Maintenance Agreement Policy Committee’s (NMAPC) Zero Incident Safety Award (ZISA) Certificate of Merit. The project totaled over 266,000 hours worked.

Lean/IPD Practices

- 6S Jobsite

- Co-Location + Big Room

- Early Selection

- Joint Control

- Last Planner® System

- Target Value Delivery

- Visual Management