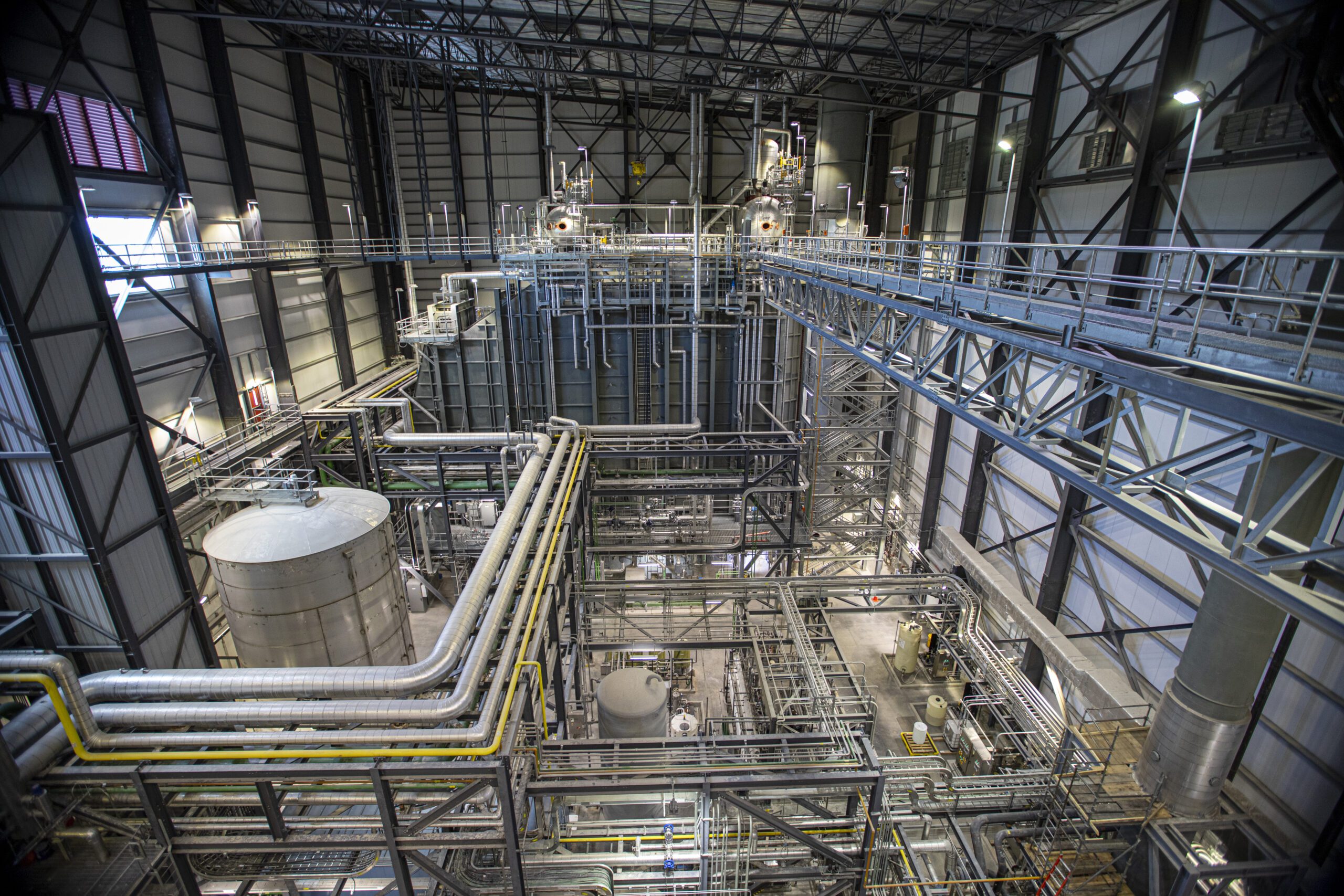

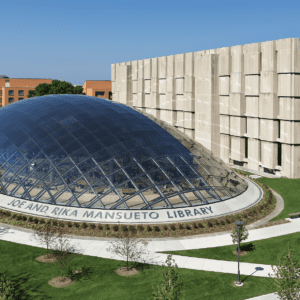

Barton Malow delivers exceptional value in large part due to our self-perform trades and ability to complete work with our own forces. We provide comprehensive boilermaker, civil/concrete, controlled environments, general trades and interiors, refractory, rigging and millwright, and structural steel services. By self-performing on our projects, we have superior control over safety, quality, cost, schedule, and even equipment. From preconstruction through punchlist, we have complete oversight with the quality of workmanship and safety on the worksite.

Even when we do not self-perform work, our self-perform trades benefit the project. Our knowledge of what the work entails improves our ability to assess subcontractors’ work and hold them accountable in their staffing, scheduling, estimating, and quality.

Our quality tradespeople are the key to utilizing their specific expertise to its greatest potential, driving the building process, and bringing projects to life.